Mastering In-Mold Decorations: Methods, Trends, and Finest Practices for Optimal Results

In the world of manufacturing, the art of in-mold decors stands as a critical facet of product style and manufacturing. As industries consistently look for innovative methods to boost aesthetic appeal and performance, mastering the ins and outs of in-mold decors has arised as a critical skill collection. From selecting the best products to including advanced style fads, the journey towards accomplishing optimum results in this domain is diverse. By diving right into the approaches, trends, and finest methods that underpin effective in-mold decor processes, companies can unlock a world of opportunities that not just boost the aesthetic allure of their products however likewise enhance manufacturing performance and bolster consumer engagement.

Material Option

Material option is an important element of mastering in-mold decors, as it directly influences the quality and durability of the last item. When selecting products for in-mold decorations, it is crucial to think about factors such as compatibility with the molding process, the wanted aesthetic end result, and the environmental conditions the item will deal with.

Moreover, the chosen product should possess excellent adhesion buildings to guarantee that the decor adheres firmly to the substratum throughout the molding process. Bond in between the design and the product is crucial for avoiding delamination and making certain long-lasting visual charm. Additionally, materials with high warm resistance are favored for in-mold decorations, especially for products that will be subjected to raised temperature levels during their lifecycle. By thoroughly choosing the proper product for in-mold decors, suppliers can enhance the overall high quality and toughness of their items, fulfilling the assumptions of both end-users and customers.

Style Technology

An important consider advancing the area of in-mold decors is the constant exploration and implementation of design technology strategies. Style development plays an important role in boosting the visual charm, functionality, and total top quality of products manufactured making use of in-mold design processes. By including ingenious design components, makers can differentiate their items out there, attract customers, and stay ahead of rivals.

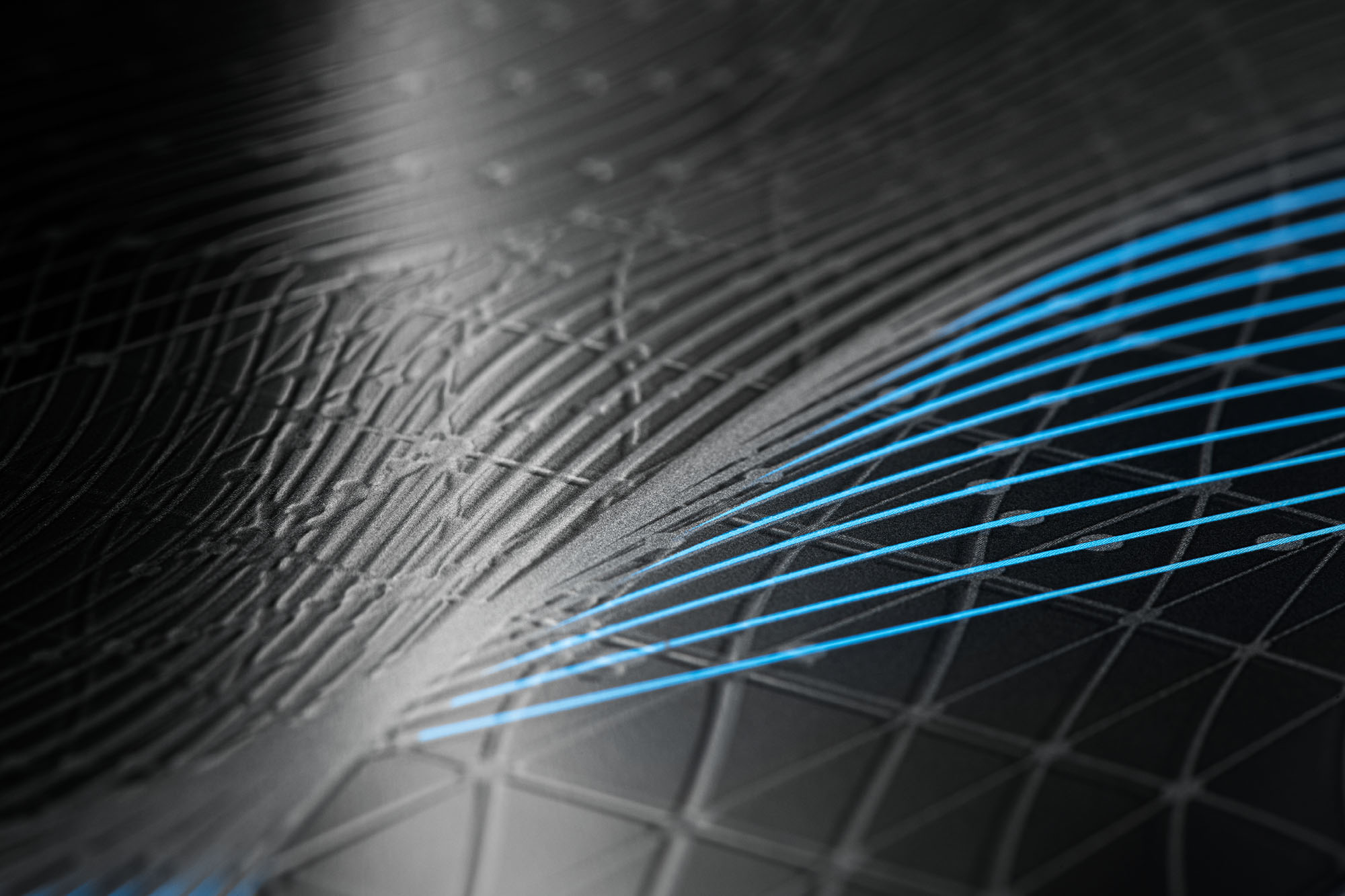

One of the vital elements of design advancement in in-mold designs is the assimilation of complex patterns, textures, and graphics that were formerly challenging to accomplish with conventional decor techniques. Advanced modern technologies such as 3D printing and electronic design devices enable developers to create facility and detailed styles that can be seamlessly moved onto shaped parts. In addition, using dynamic colors, metal finishes, and special results like gloss or matte textures can additionally boost the visual allure of in-mold decorated products.

In addition, design advancement expands beyond aesthetics to include useful improvements such as ergonomic shapes, integrated attributes, and customizable elements that accommodate details user requirements. By accepting layout innovation, producers can open brand-new opportunities for customization, creativity, and product distinction in the affordable landscape of in-mold decorations.

Production Efficiency

Reliable production processes are essential for converting the ingenious styles developed in the area of in-mold designs into high-grade ended up products that fulfill market needs and consumer assumptions. In the realm of in-mold decorations, manufacturing efficiency includes various key elements that contribute to the total success of the manufacturing procedure.

Automation not only accelerates the production process however likewise improves accuracy and repeatability, leading to an extra high-quality and uniform end product. In general, a holistic method to production effectiveness is critical in optimizing the capacity of in-mold design methods and accomplishing optimum outcomes in the competitive market landscape.

Quality Assurance Steps

What are the essential techniques for guaranteeing strict quality control measures in the world of in-mold decors? Quality assurance procedures are critical in in-mold decoration processes to make certain the manufacturing of top quality and flawless ended up items. One important approach is the implementation of rigorous examination procedures at every stage of the manufacturing process. This involves performing complete visual examinations, dimensional checks, and shade consistency analyses to determine any inconsistencies or flaws at an early stage.

Utilizing sophisticated modern over here technologies such as automatic examination systems can also improve the top quality control process by supplying accurate and reputable information for analysis. These systems can identify flaws that might be missed out on by manual examinations, consequently improving overall item top quality and consistency.

Routine training and advancement programs for staff members involved in the in-mold design procedure can additionally add to maintaining premium criteria. By educating staff on finest methods, top quality assumptions, and the visit importance of attention to detail, business can promote a society of top quality awareness throughout the organization.

Consumer Appeal

To boost the marketability of in-mold decoration items, comprehending and providing to customer choices play a vital duty in identifying their appeal and success. Supplying personalization options such as tailored styles, shade variations, and textural components can substantially enhance the allure of in-mold decoration items.

Verdict

In-mold designs provide a reliable and functional method have a peek here to enhance product aesthetics. Understanding in-mold designs needs a holistic strategy that takes into consideration all elements of the manufacturing procedure to guarantee success.

In the realm of production, the art of in-mold designs stands as a pivotal facet of item design and manufacturing. Style innovation plays a critical function in enhancing the visual charm, capability, and general quality of items manufactured making use of in-mold design procedures.One of the essential facets of style innovation in in-mold decors is the integration of detailed patterns, structures, and graphics that were formerly challenging to attain with conventional decor methods.Effective production processes are essential for equating the cutting-edge styles created in the field of in-mold designs right into top quality ended up products that satisfy market needs and consumer expectations. Using customization choices such as tailored designs, color variants, and textural components can considerably enhance the appeal of in-mold design items.